Self-Closing Braided Sleeving, a convenient cable management product. Its unique self-locking design allows for easy installation and quick removal. The braided material is soft and durable, effectively protecting the cable from abrasion. At the same time, it has excellent expansion and contraction properties to accommodate cables of different diameters. Whether it's for everyday wiring in the home or for industrial applications, it's easy to manage cables neatly and safely.

Advantages

1. Self-Closing Design: The sleeving features a unique self-closing mechanism that eliminates the need for additional ties or fasteners. Its braided structure automatically expands (up to 150% of its nominal diameter) to accommodate cables and retracts securely around them, ensuring a snug fit. This design reduces installation time by approximately 30% compared to traditional sleeving.

2. High-Temperature Resistance: Constructed from flame-retardant polyester or nylon materials, the sleeving withstands temperatures ranging from -40°C to 150°C (-40°F to 302°F). It meets UL 94V-2 flammability standards, making it suitable for industrial and automotive applications.

3. Abrasion & Chemical Resistance: The braided design provides exceptional abrasion resistance, withstanding over 50,000 back-and-forth cycles (ASTM D4966). It also resists common chemicals like oils, acids, and alkalis, maintaining integrity even in harsh environments.

4. EMI/RFI Protection (Optional): Certain variants incorporate conductive fibers (e.g., nickel/copper-coated polyester) offering 85-90% shielding effectiveness (per MIL-STD-285) against electromagnetic or radio frequency interference, critical for sensitive electronics.

5. Lightweight & Flexible: With a typical weight of 0.05-0.15g/cm³ (depending on diameter), the sleeving adds minimal bulk while maintaining a bend radius as low as 4x its diameter, ideal for tight spaces.

6. Color Coding & Customization: Available in standard colors (black, gray, orange) with optional stripes or prints for wire identification. Custom diameters range from 3mm to 50mm, accommodating various bundle sizes.

Applications

Cable Management: Self-closing braided sleeving is widely used in cable management to organize and protect wires and cables. It helps maintain a neat and organized appearance while preventing damage due to friction or external elements.

Cable Management: Self-closing braided sleeving is widely used in cable management to organize and protect wires and cables. It helps maintain a neat and organized appearance while preventing damage due to friction or external elements.

Electronics and Wiring Harnesses: It is commonly employed in the electronics industry to protect and bundle wiring harnesses. The sleeving ensures the integrity of the wiring and prevents issues arising from exposure to harsh environments.

Automotive Sector: Self-closing braided sleeving finds applications in the automotive sector for protecting and managing wires and cables in vehicles. It helps prevent wear and abrasion caused by vibrations and movement.

Industrial Machinery: In industrial settings, this type of braided sleeving is utilized to safeguard cables and hoses on machinery, providing insulation and protection against physical stress.

Audiovisual Equipment: The sleeving is often used in the audiovisual industry to organize and protect cables associated with audio and video equipment, ensuring reliable performance.

Medical Devices: In certain medical applications, self-closing braided sleeving is used to protect and manage wiring in medical devices, providing a secure and durable solution.

These applications demonstrate the versatility of self-closing braided sleeving in various industries where cable protection and organization are essential.

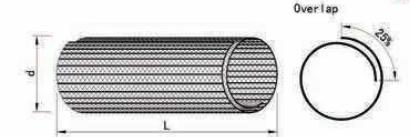

Engineering Picture:

FAQ:

Braided self-closing sleeving provides a cost-effective solution for protecting wire harnesses from mechanical damage and strain. It is lightweight, easy to install, and available in a wide range of sizes and lengths to accommodate different applications. The self-closing feature eliminates the need for additional fasteners, simplifying installation and reducing assembly time.

Braided self-closing sleeving is commonly used in automotive, industrial, and electronic applications, where protection from mechanical damage and strain is required. It is also commonly used in home appliances, consumer electronics, and other products that require wire harnesses with reliable protection.

There are several different types of braided self-closing sleeving available, including single-layer and double-layer braiding, different sizes and lengths, and with or without a protective outer jacket. The type of sleeving chosen depends on the specific application requirements, such as the level of protection required and the type of mechanical damage that needs to be mitigated.

Braided self-closing sleeving works by providing a protective layer around the wire that shields it from external mechanical damage and strain. The braided material effectively absorbs tensile and compressive forces, reducing the risk of wire damage or failure. The self-closing feature allows for easy installation and strain-relief, ensuring the wire harness remains securely in place

Product Part | d: Inner Diameter (mm) | Maximum Wrap Diameter (mm) | Packing (Length/Coil) |

SCW-006 | 6 | 7 | 100M |

SCW-009 | 9 | 10 | 100M |

SCW-013 | 13 | 14 | 100M |

SCW-016 | 16 | 17 | 50M |

SCW-019 | 19 | 20 | 50M |

SCW-025 | 25 | 26 | 25M |

SCW-032 | 32 | 33 | 25M |

SCW-038 | 38 | 40 | 25M |

SCW-050 | 50 | 52 | 25M |

Material | Polyester Monofilament + Polyester Multifilament |

Operating Temperature | -50℃-+150℃ |

Melting Point | 240℃±10℃ |

Flame Resistance Rating | UL94-V1 |

Certificate | RoHS, REACH |

Standard Colors | Black |

Cutting Tool | Hot Knife Cutter |