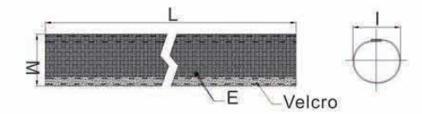

Hook-and-Loop Self-Closing Braided Sleeving

The Velcro/Hook-and-Loop Self-Closing Braided Sleeving is a convenient cable management solution. Its unique self-locking Velcro design makes installation and removal simple and easy. The braided material is soft and durable, effectively protecting the cable from abrasion and external interference. At the same time, it has good stretchability and is suitable for cable bundles of different diameters. Whether for home wiring or industrial applications, this self-closing braided sleeving provides a neat and secure cable management experience.

The Velcro/Hook-and-Loop Self-Closing Braided Sleeving is a convenient cable management solution. Its unique self-locking Velcro design makes installation and removal simple and easy. The braided material is soft and durable, effectively protecting the cable from abrasion and external interference. At the same time, it has good stretchability and is suitable for cable bundles of different diameters. Whether for home wiring or industrial applications, this self-closing braided sleeving provides a neat and secure cable management experience.

Convenient Management and Organization:

The Velcro self-closing feature makes the sleeving easy to open and close, facilitating convenient cable management. This design allows users to add or remove cables effortlessly without the need for additional tools.

Easy Installation:

Due to the Velcro self-closing mechanism, this braided sleeving is typically easy to install, requiring no extra accessories such as ties or other fastening devices.

Durable and Abrasion-Resistant:

Braided protective sleeves are often made from durable materials, providing excellent resistance to abrasion and protecting cables from environmental factors.

Aesthetic Appeal:

The sleeving design contributes to a neat appearance, helping to keep cable organization orderly and reduce clutter.

Variety of Sizes and Colors:

This type of sleeving usually comes in various sizes and color options to meet different needs and scenarios.

1. Chemical Processing

Use Case: Transport of aggressive acids, solvents, and corrosive chemicals.

Why PVDF: Exceptional chemical resistance, high purity, and low permeability.

Industries: Chemical plants, refineries, electroplating, acid dosing systems.

2. Semiconductor Manufacturing

Use Case: Ultra-clean fluid transport in wafer fabrication and chip production.

Why PVDF: High purity, low extractables, compatible with ultra-pure water and aggressive etchants.

Industries: Semiconductor fabs, cleanroom environments, electronics.

3. Pharmaceutical & Biotechnology

Use Case: Tubing for transferring sensitive media and cleaning agents.

Why PVDF: Biocompatible, sterilizable, resistant to SIP/CIP, and compliant with FDA & USP standards.

Industries: Biotech labs, pharmaceutical production, vaccine development facilities.

4. Water Treatment & Filtration Systems

Use Case: Tubing for transporting ozone, chlorine, and other strong oxidizers.

Why PVDF: UV resistance, high oxidative stability, and long service life.

Industries: Industrial water treatment, ultrapure water systems, municipal filtration plants.

5. Food & Beverage Processing

Use Case: Transport of CIP chemicals or direct contact with food-safe fluids.

Why PVDF: FDA-compliant, smooth inner walls, resistant to cleaning agents.

Industries: Dairy processing, brewing, beverage dispensing systems.

FAQ:

Braided velcro self-closing sleeve offers a combination of secure fastening and protection from abrasion and wear. The velcro fasteners provide easy and secure closing, while the braided sleeve adds an additional layer of protection and durability. This type of sleeve also provides a more finished and professional appearance.

Braided velcro self-closing sleeve is commonly used in a variety of applications, including clothing, bags, luggage, and more. It is particularly useful for items that require secure fastening and protection from wear and abrasion.

There are several different types of braided velcro self-closing sleeve available, including single-layer and double-layer braiding, different sizes and lengths, and with or without a protective outer jacket. The type of sleeve chosen depends on the specific application requirements, such as the level of protection needed and the type of material being used.

Braided velcro self-closing sleeve works by using a combination of velcro fasteners and braided sleeves. The velcro fasteners are securely attached to the braided sleeve, allowing for easy and secure closing. When pressed together, the hooks on one piece of velcro engage with the loops on the other piece, creating a secure seal. The braided sleeve covers the velcro fasteners, providing protection from abrasion and wear while also enhancing the appearance of the item.

| Product Part | Flat Width (mm) | Hook-and-Loop Width (mm) | Expanded Width(mm) | Packing (Length/Coil) |

VCW-013 | 13 | 10 | 10 | 25M |

VCW-019 | 19 | 10 | 15 | 25M |

VCW-032 | 32 | 20 | 20 | 25M |

VCW-051 | 51 | 20 | 30 | 25M |

VCW-064 | 64 | 20 | 45 | 25M |

Material | Polyester |

Hook-and-Loop Material | Nylon |

Operating Temperature | -50℃-+150℃ |

Melting Point | 240℃±10℃ |

Flame Resistance Rating | UL94 V2 |

Certificate | RoHS, Halogen-Free |

Standard Colors | Black |

Cutting Tool | Hot Knife Cutter |