Tinned Copper Shielded Self-Closing Sleeving, an efficient cable protection product. Its unique self-locking design makes installation and removal easy and quick. Tinned Copper Shielded Self-Closing Sleeving protects against electromagnetic interference and ensures stable signal transmission. At the same time, the material is soft and durable, protecting the cable from abrasion. Whether for home or industrial applications, it provides a safe and neat cable management solution to ensure the stable operation of electrical equipment.

Features & Technical Performance

Wide Temperature Resistance

Operating Temperature: -60℃ to +200℃

Maintains structural integrity under high heat and remains flexible in extreme cold, suitable for engine compartments, industrial machinery, and outdoor applications.

High Melting Point Material

Melting Point: 285℃ ±10℃

Ensures no melting, dripping, or deformation even under thermal overload or short-term high temperature exposure.

Electromagnetic Shielding Efficiency

Shielding Effectiveness: ≥ 60 dB (10 MHz – 1 GHz)

Effectively blocks EMI/RFI, ensuring stable data transmission in CAN-bus, communication, and signal cables.

Flame Retardant Safety

Flame Rating: UL94 V0 / VW-1

Meets industrial and automotive fire protection standards, self-extinguishes within 10 seconds without flaming drips.

Corrosion & Oxidation Resistance

Material: Tinned Copper (3× higher anti-oxidation performance)

Maintains conductivity and shielding even in high humidity, salt spray, or corrosive industrial environments.

High Conductivity for Shield Grounding

Electrical Resistivity: ≤ 0.020 Ω·mm²/m

Supports reliable grounding pathways, maintaining continuous shielding integrity.

Self-Closing Wrap Structure

Overlap Coverage: 25% Self-Locking Design

Enables easy installation without disconnecting connectors—ideal for retrofitting and maintenance work.

Mechanical Durability

Bending Life: > 50,000 flex cycles

Resists abrasion, vibration, and repeated bending, ensuring long-term protection.

Dual Protection: Shielding + Abrasion Resistance

Provides both electromagnetic shielding and mechanical protection, extending cable service life by over 30%.

Stable Signal Transmission with No Crosstalk

Ideal for data and sensor lines, reducing signal loss and interference in high-speed applications.

Maintenance-Friendly & Reusable

Self-wrapping design eliminates the need for heat shrinking or tape, improving service efficiency by 40%.

Compliant with Industry Standards

Meets RoHS, UL, Automotive OEM, Railway, and Industrial specifications.

Built for Harsh Environments

Heat-resistant, corrosion-resistant, and impact-resistant—designed for automotive, aerospace, telecom, and heavy industry.

Electronics and Electrical Wiring: Used to protect and shield wires and cables in electronic devices, appliances, and electrical installations, especially in environments where electromagnetic interference must be minimized.

Electronics and Electrical Wiring: Used to protect and shield wires and cables in electronic devices, appliances, and electrical installations, especially in environments where electromagnetic interference must be minimized.

Data and Communication Cabling: Applied in data centers, networking installations, and communication systems to prevent interference and maintain signal integrity.

Industrial Control Systems: Suitable for use in industrial settings where electrical equipment is exposed to harsh conditions or where electromagnetic interference could affect the performance of control systems.

Medical Devices: Used in medical equipment and devices to ensure the integrity of sensitive electronic components and signals.

Aerospace and Defense: Applied in aerospace and defense applications where reliability and electromagnetic compatibility are critical for the proper functioning of electronic systems.

Automotive Electronics: Used to protect wiring and cables in vehicles, providing shielding against electromagnetic interference that could affect the performance of electronic systems in automobiles.

Renewable Energy Systems: Applied in solar power and wind energy installations to protect wiring from environmental factors and electromagnetic interference.

These applications highlight the versatility of tinned copper shielded self-closing sleeving in various industries where reliable and secure wire protection is essential.

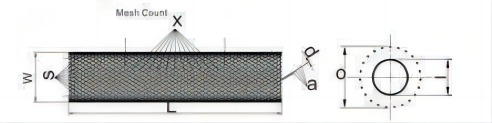

Engineering Picture

FAQ:

Tinned copper shielded self-closing sleeving provides a cost-effective solution for protecting electronic wire harnesses from EMI interference and mechanical damage. It is lightweight, easy to install, and available in a wide range of sizes and lengths to accommodate different applications. The self-closing feature eliminates the need for additional fasteners, simplifying installation and reducing assembly time.

Tinned copper shielded self-closing sleeving is commonly used in aerospace, military, and automotive applications, where EMI protection and high-performance wire harnesses are required. It is also commonly used in industrial control systems, medical equipment, and other electronic systems that require protection from EMI interference and mechanical damage.

There are several different types of tinned copper shielded self-closing sleeving available, including single-layer and double-layer shielding, different sizes and lengths, and with or without a protective outer jacket. The type of sleeving chosen depends on the specific application requirements, such as the level of EMI protection required and the type of mechanical damage that needs to be mitigated.

Tinned copper shielded self-closing sleeving works by providing a protective layer around the core wire that shields it from external EMI interference and mechanical damage. The shielding layer is made of braided copper wire that effectively blocks incoming and outgoing electromagnetic fields, reducing EMI interference and protecting the wire harness from mechanical damage. The self-closing feature allows for easy installation and strain-relief, ensuring the wire harness remains securely in place

Product Part | Functional Inner Diameter (mm) | Overlap Rate | Packing (Length/Coil) |

DXTF-005 | 3-6 | 25% | 100M |

DXTF-009 | 7-10 | 25% | 100M |

DXTF-013 | 11-14 | 25% | 50M |

DXTF-019 | 15-20 | 25% | 25M |

DXTF-025 | 21-26 | 25% | 25M |

DXTF-032 | 27-33 | 25% | 25M |

Material | Tinned Copper Wire, PPS Monofilament |

Operating Temperature | -60℃-+200℃ |

Melting Point | 285±10℃ |

Flame Resistance Rating | UL94 V0、VW-1 |

Certificate | RoHS |

Standard Colors | Natural Color |

Cutting Tool | Scissors |