When choosing tubing materials for industrial, medical, laboratory, or electronics applications, many engineers ask: Is PTFE tubing flexible? The answer is yes, but its flexibility depends on several factors—diameter, wall thickness, temperature, and the specific application. To fully understand this, we must first look at what PTFE tubing is, how it behaves mechanically, and how it compares to other materials such as Kynar plastic and Silicone Heat Shrink tubing.

This article offers an in-depth explanation of PTFE tubing flexibility, performance features, applications, and how it compares to similar products.

What Is PTFE Tubing?

Before discussing flexibility, let’s clarify: What is PTFE tubing?

PTFE, also known by its brand name Teflon, is a fluoropolymer with exceptional chemical resistance, thermal stability, and low friction. PTFE tubing (or Teflon tubing) is a hollow tube extruded from pure PTFE resin. It is widely used in environments requiring:

High temperatures

Harsh chemical exposure

Electrical insulation

Extremely smooth internal surfaces

Non-reactive and non-stick characteristics

Because PTFE is so chemically inert, it is also a common material used for PTFE gasket production.

Is PTFE Tubing Flexible? The Short Answer

Yes — PTFE tubing is flexible, but not in the same way as silicone or rubber.

PTFE is a semi-rigid fluoropolymer, meaning:

It bends, but does not stretch.

It is flexible, but not “soft.”

Thinner-wall PTFE tubing offers more pliability.

Larger-size PTFE tubes are stiffer due to geometry.

In most industrial applications, PTFE tubing is considered moderately flexible, capable of bending without breaking but maintaining its shape.

What Determines PTFE Tubing Flexibility?

Several factors affect how flexible or rigid PTFE tubing feels:

1. Wall Thickness

Thin-wall PTFE tubing → more flexible, easy to route around corners.

Thick-wall PTFE tubing → more rigid, better for high-pressure applications.

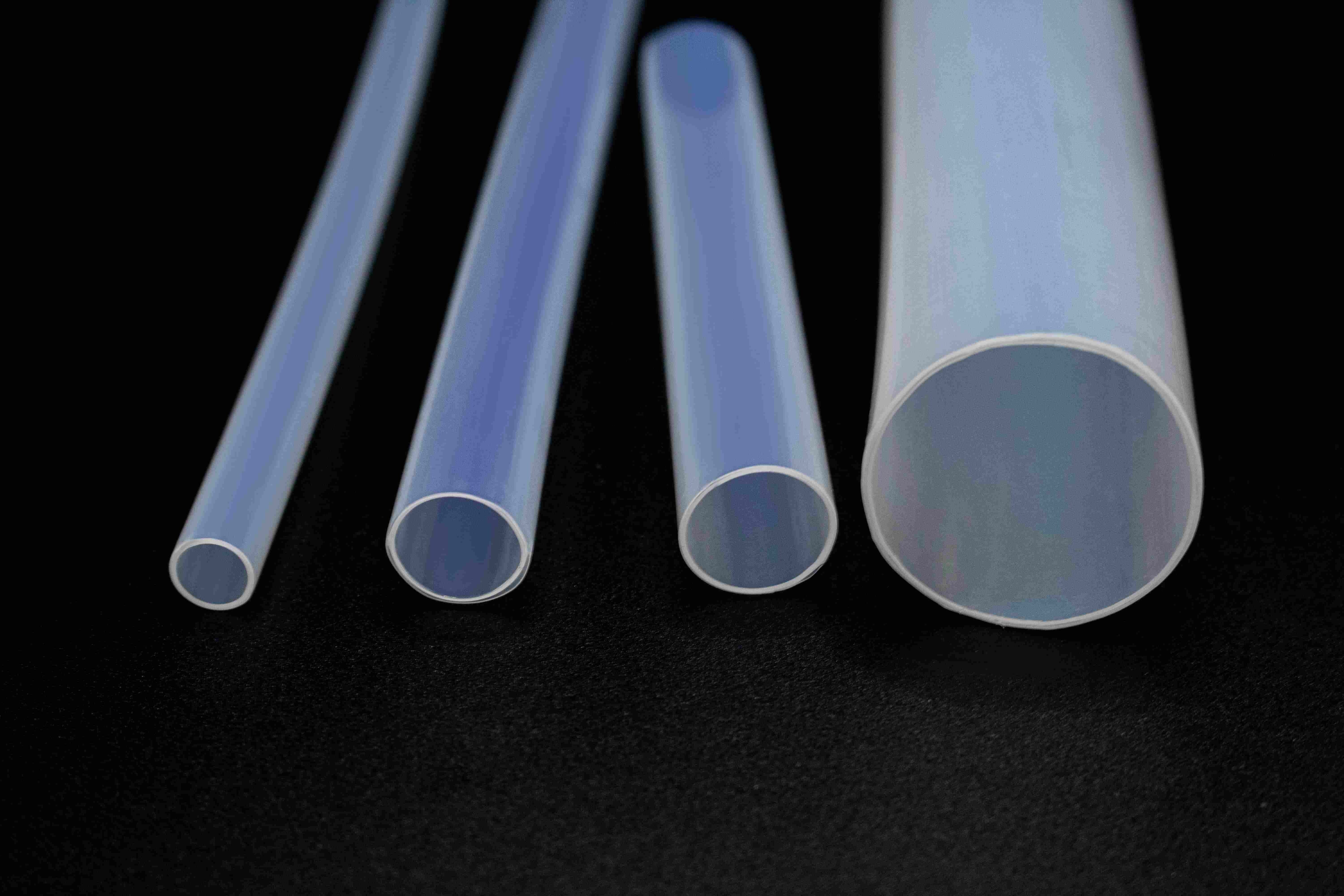

2. Tube Diameter

Smaller inner diameters are generally easier to bend. Larger tubes require more force and may maintain a straight shape unless heated.

3. Temperature

PTFE becomes softer and more flexible when heated. Flexibility improves significantly above:

80–100°C for general bending

150°C+ for tight-radius bends

This is why PTFE is often thermoformed for custom shapes.

4. Manufacturing Process

Some PTFE tubes are made from paste extrusion (more flexible), while others are made using ram extrusion (slightly more rigid).

Why PTFE Tubing Is Still Considered Flexible

Compared with metals or rigid plastics, PTFE tubing offers several flexibility advantages:

It can bend without cracking.

It tolerates repeated bending cycles better than brittle plastics.

It retains flexibility across a wide temperature range (−200°C to +260°C).

This makes PTFE tubing, Teflon tubing, and various PTFE gasket components preferred for dynamic, high-performance systems.

How Flexible Is PTFE Tubing Compared to Other Materials?

To better understand PTFE flexibility, let’s compare it with several commonly used tubing materials.

PTFE Tubing vs. Kynar Plastic (PVDF Tubing)

Kynar plastic (PVDF) is another high-performance fluoropolymer but offers greater rigidity than PTFE.

| Property | PTFE Tubing | Kynar Plastic (PVDF) |

|---|---|---|

| Flexibility | Moderate | Lower (more rigid) |

| Chemical Resistance | Excellent | Very good |

| Temperature Resistance | Up to 260°C | Up to 150°C |

| Cost | Higher | Moderate |

Conclusion:

If maximum chemical and thermal resistance are needed, PTFE tubing is the better choice. If a slightly rigid structure is desired, Kynar plastic is ideal.

PTFE Tubing vs. Silicone Heat Shrink Tubing

Silicone heat shrink tubing has a completely different type of flexibility. Silicone is:

Soft

Elastic

Stretchable

Compressible

In comparison:

| Property | PTFE Tubing | Silicone Heat Shrink Tubing |

|---|---|---|

| Flexibility | Semi-rigid | Very soft and flexible |

| Elasticity | Non-elastic | Highly elastic |

| Chemical Resistance | Excellent | Moderate |

| Heat Shrink | No | Yes |

Conclusion:

If you need soft, rubber-like flexibility, silicone heat shrink tubing is best. If the application demands chemical resistance and high temperatures, PTFE tubing is the superior choice.

Why PTFE Tubing Is Used Even If It’s Not Extremely Soft

Even though PTFE tubing is not as flexible as silicone or rubber, engineers still select it because:

1. It withstands extreme temperatures

PTFE remains stable from -200°C to 260°C, which very few materials can match.

2. It is chemically inert

PTFE tubing resists nearly all acids, solvents, fuels, and corrosive chemicals.

3. It has the lowest friction coefficient of any solid

This allows smooth fluid or gas flow with minimal pressure drop.

4. It provides excellent electrical insulation

Common in high-voltage, RF, and aerospace applications.

5. It is non-stick and low absorption

Fluids flow cleanly, making it ideal for pharmaceutical and laboratory environments.

6. It handles UV and weather exposure well

PTFE does not degrade outdoors.

Where PTFE Tubing Flexibility Matters Most

Though semi-rigid, PTFE tubing is used in many flexible-routing systems such as:

1. Chemical Transfer Lines

Its inertness allows safe transport of acids, solvents, and reactive fluids.

2. Medical Equipment

Flexible PTFE tubing is used for catheter liners, surgical tools, and lab analysis.

3. Electrical Insulation

PTFE tubing provides bendable yet durable insulation for wiring in:

Aerospace

Automotive

Electronics

Telecommunications

4. Semiconductor Manufacturing

PTFE tolerates aggressive etching chemicals while routing easily in tight spaces.

5. Food and Beverage Processing

Its non-stick properties prevent contamination and buildup.

6. 3D Printers and CNC Machines

PTFE tubes guide filament or air lines with smooth low-friction pathways.

How to Make PTFE Tubing More Flexible

If your application requires additional flexibility, you can modify PTFE tubing performance by:

1. Choosing thin-wall designs

These bend more easily without losing durability.

2. Increasing temperature

Heating PTFE to around 100–150°C makes it bend easily for shaping.

3. Using corrugated PTFE tubing

This increases flexibility dramatically for vacuum or robotics applications.

4. Selecting smaller diameters

Narrow tubes bend more naturally.

Applications Where PTFE Flexibility Is Critical

1. Robotic Arms

PTFE tubing routes air or chemicals with minimal friction.

2. Analytical Instruments

Precise, smooth fluid flow is essential.

3. High-Temperature Furnaces

Flexible routing helps avoid sharp bends that may crack other tubing types.

4. Automotive Fuel Lines

PTFE withstands ethanol, gasoline, and high heat.

5. Pharmaceutical Transfer

Flexible PTFE ensures contamination-free fluid movement.

Is PTFE Tubing the Right Choice for Your Project?

You should choose PTFE tubing or Teflon tubing if your application requires:

Exceptional chemical resistance

High temperature endurance

Smooth, low-friction fluid movement

Nonstick interior

Durable yet moderately flexible routing

If you need soft, elastic flexibility, then silicone heat shrink tubing is more suitable.

If you want a rigid, chemical-resistant structure, Kynar plastic may be better.

Conclusion: PTFE Tubing Is Flexible — But With Limits

So, is PTFE tubing flexible?

Yes, PTFE tubing offers moderate flexibility, especially in thin-wall and small-diameter formats. While not as soft as silicone, it provides a unique combination of:

Flexibility

Strength

Chemical resistance

Temperature stability

Nonstick performance

This balance makes PTFE tubing, Teflon tubing, and PTFE gasket components essential across industries—from aerospace to medical, from chemical processing to electronics.