In the realm of medical device manufacturing, precision, reliability, and safety are paramount. Among the various materials utilized, FEP (Fluorinated Ethylene Propylene) heat shrink tubing stands out as a critical component, offering a combination of properties that make it indispensable in the production of medical devices. This article delves into the reasons why FEP Heat Shrink Tubing is essential in this field, highlighting its unique characteristics and applications.

Understanding FEP Heat Shrink Tubing

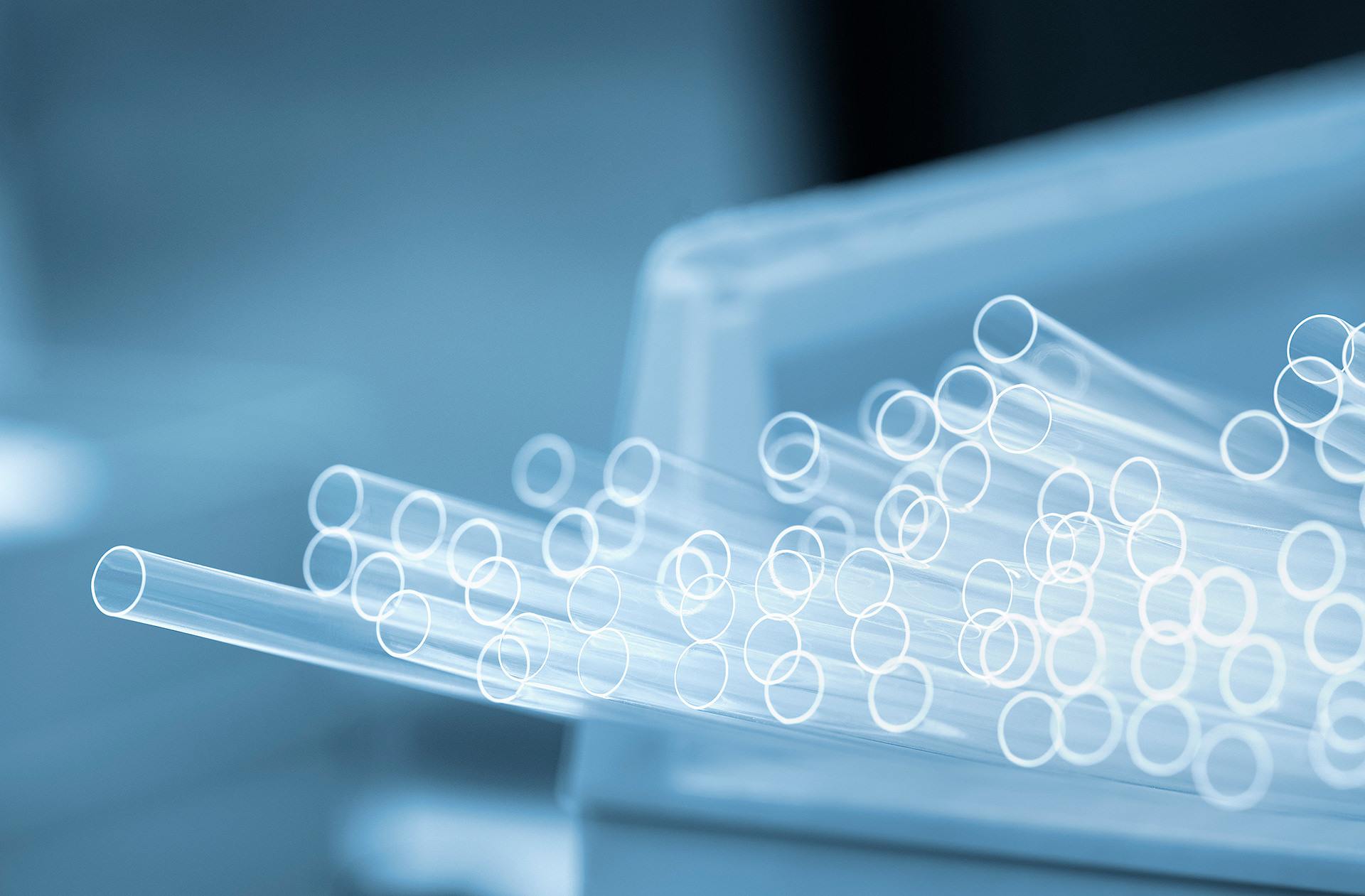

FEP Heat Shrink Tubing is a type of Fluoropolymer Tubing that, when heated, shrinks to fit the contours of underlying components. This shrinkage provides a tight, protective cover, ensuring that the tubing conforms precisely to the shape of the device. The material's inherent properties, such as chemical resistance, thermal stability, and biocompatibility, make it particularly suited for medical applications where these attributes are crucial.

Key Properties Beneficial to Medical Devices

Chemical Resistance: Medical devices often come into contact with various chemicals during their use and sterilization processes. FEP tubing offers exceptional resistance to a wide range of chemicals, ensuring that the devices remain unaffected by exposure to these substances. This resistance is vital in maintaining the integrity and functionality of medical instruments.

Thermal Stability: The manufacturing and sterilization processes for medical devices frequently involve exposure to high temperatures. FEP heat shrink tubing can withstand these elevated temperatures without degrading, ensuring that the protective covering remains intact and effective throughout the device's lifecycle.

Biocompatibility: For medical devices that are implanted or come into direct contact with body tissues, biocompatibility is a critical consideration. FEP tubing is biocompatible, meaning it does not induce an immune response when in contact with bodily tissues, making it safe for use in such applications.

Optical Clarity: The transparency of FEP tubing allows for visual inspection of the underlying components. This optical clarity is particularly beneficial during the manufacturing process, as it enables quality control personnel to detect any defects or inconsistencies in the device assembly.

Lubricity and Flexibility: FEP tubing exhibits low friction and high flexibility, which is advantageous in applications where the tubing needs to navigate through tight spaces or complex pathways. This flexibility ensures that the tubing can be easily manipulated during the assembly of medical devices.

Applications in Medical Device Manufacturing

FEP heat shrink tubing finds application in various aspects of medical device manufacturing:

Catheter Construction: FEP tubing is commonly used in the construction of catheters, providing a protective layer that ensures the catheter's structural integrity and functionality.

Wire Insulation: The tubing serves as an insulating layer for wires within medical devices, preventing electrical interference and ensuring the safety of the device.

Protective Coverings: FEP tubing is used as a protective covering for various components, shielding them from environmental factors and physical damage.

Sterilization: The material's ability to withstand high temperatures makes it suitable for use in devices that undergo sterilization processes, ensuring that the protective covering remains intact and effective.

Conclusion

FEP heat shrink tubing plays a pivotal role in medical device manufacturing, offering a combination of properties that ensure the safety, reliability, and functionality of medical devices. Its chemical resistance, thermal stability, biocompatibility, optical clarity, and flexibility make it an indispensable material in the production of high-quality medical instruments. As the healthcare industry continues to evolve, the demand for materials like FEP heat shrink tubing will undoubtedly increase, underscoring its essential role in advancing medical technology.