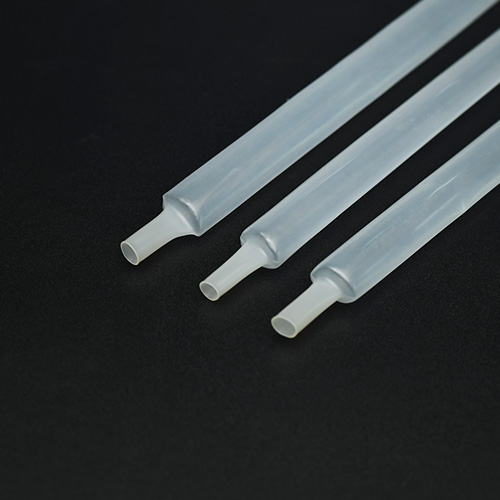

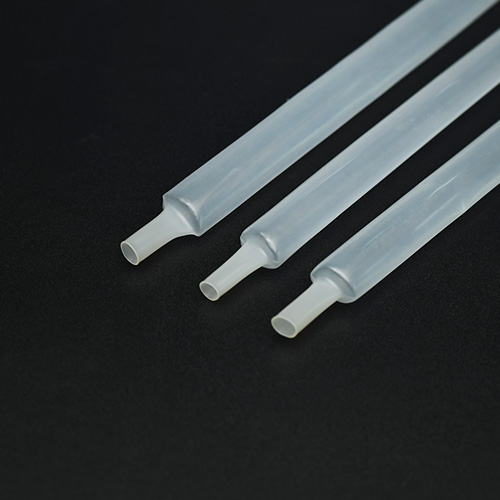

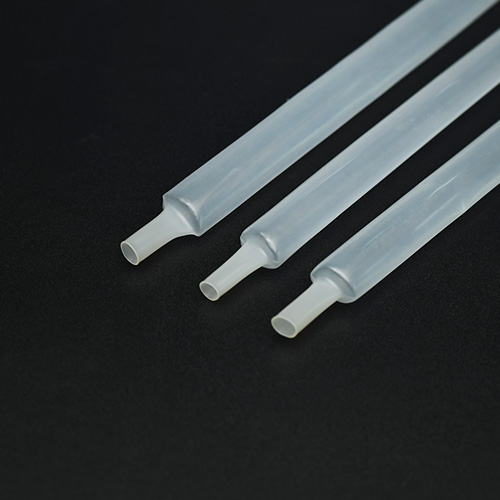

PVDF Heat Shrink TUBING/KYNAR TUBING

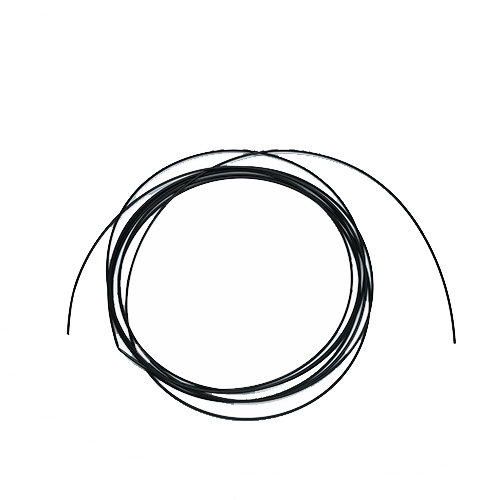

PVDF Heat Shrink Tubing, also known as Kynar Heat Shrink Tubing, is a high-performance thermoplastic polymer renowned for its outstanding chemical resistance, thermal stability, and durability. With a shrink ratio of 2:1, this tubing provides reliable insulation and protection for wires, cables, pipes, and sensitive components in extreme environments. Its superior UV and flame resistance make it ideal for applications across automotive, aerospace, medical, electronics, and chemical industries.

Manufactured with high-purity PVDF, Kynar Heat Shrink Tubing is free from additives and contamination, making it suitable for critical applications such as semiconductor manufacturing and medical devices.

Heat Shrinkability: Shrinks under heat to conform tightly to the covered object, ensuring secure insulation.

Chemical Resistance: Resistant to acids, bases, and other corrosive chemicals.

Thermal Resistance: Operates reliably at continuous temperatures up to 150°C and short peaks up to 175°C.

Weatherability: Excellent UV and radiation resistance, suitable for outdoor applications.

Mechanical Strength: Maintains toughness and flexibility even at low temperatures.

Wear Resistance: High surface hardness resists abrasion and mechanical damage.

Flame Resistance: Self-extinguishing material with low combustibility.

Machinability: Easily cut, welded, or formed into custom sizes and shapes.

Translucency: Some types allow visual inspection of underlying wires or components.

Product Advantages:

Superior Protection: Shields cables, wires, and components from chemicals, UV light, and oxidation.

Stable Performance: Maintains electrical and mechanical properties under extreme conditions.

Extended Product Life: Anti-aging properties ensure long-term durability.

Environmental Adaptability: Suitable for high humidity, chemical exposure, and outdoor environments.

Ease of Installation: Heat-shrinkable design allows fast, efficient application.

Compliance: RoHS, REACH, and FDA compliant; VW-1 flame resistance rating for GD-PTFE variants.

GD-PVDF complies with RoHS, REACH, and FDA requirements.

GD-PTFE meets the VW-1 flame resistance rating.

Electronics Industry: Insulation and protection for wires, cables, and circuit boards, especially in chemically aggressive or high-temperature environments.

Automotive Industry: Protects wire harnesses, optical cables, and vehicle components from corrosion, chemical fluids, and heat.

Aerospace: Ideal for aircraft cabling and harnesses requiring extreme temperature and chemical resistance.

Medical Equipment: High-purity tubing suitable for devices contacting sensitive liquids or the human body.

Semiconductor Manufacturing: Safe pipeline material for transporting chemical reagents.

Chemical Industry: Protection for pipes and equipment against acids, alkalis, and corrosion.

Pipe & Pipeline Industry: Shields pipelines from mechanical damage, wear, and environmental hazards.

Construction & Water Conservancy: Protects pipes and connections, ensuring durability and energy efficiency.

Power Generation: Insulates and protects cables from heat, corrosion, and acid exposure.

Ensure the tubing diameter is compatible with the component before heating.

Apply uniform heat to achieve complete shrinkage without overheating.

Avoid exposure to sharp edges during installation to prevent puncture or tearing.

Store in a cool, dry place away from direct sunlight and chemical contaminants.

Q1: What is the difference between Kynar Heat Shrink Tubing and regular heat shrink tubing?

A1: Kynar heat shrink tubing is made of PVDF, providing superior chemical, thermal, UV, and flame resistance compared to standard materials like polyolefin or PVC. It is suitable for harsh and high-purity applications.

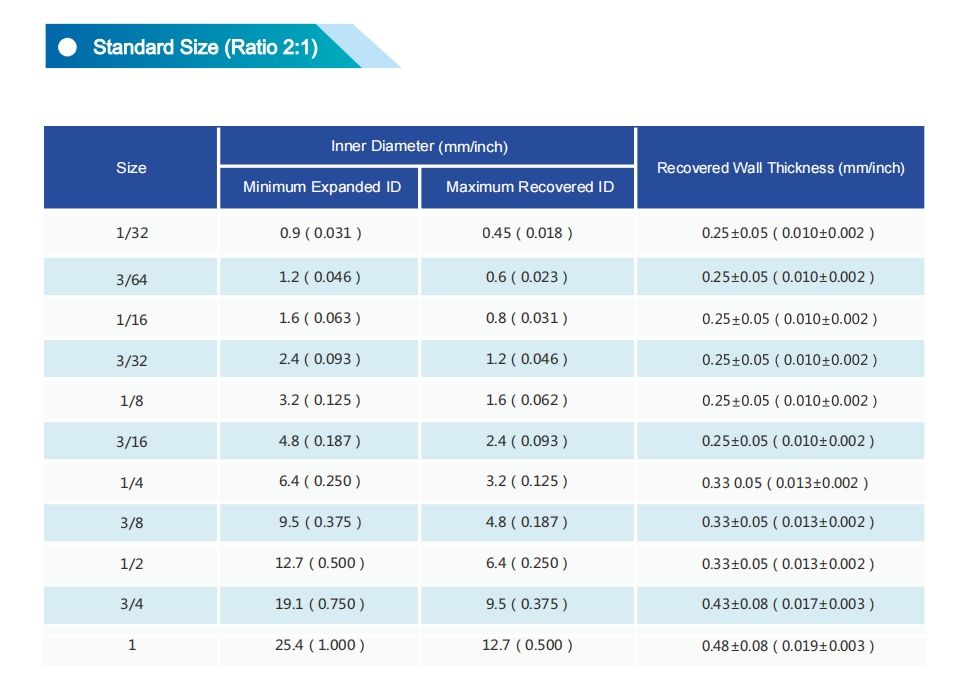

Q2: What shrink ratio does PVDF Kynar tubing offer?

A2: Most PVDF heat shrink tubing, including kynar heat shrink tubing, offers a shrink ratio of 2:1, meaning it will shrink to half its original diameter when heated.

Q3: Can Kynar heat shrink tubing be used outdoors?

A3: Yes, its excellent UV and weather resistance make it suitable for outdoor applications.

Q4: What industries commonly use PVDF heat shrink tubing?

A4: Automotive, aerospace, electronics, medical devices, chemical processing, power generation, and water conservancy industries are all common users of PVDF heat shrink tubing.

Q5: What is the maximum temperature PVDF tubing can withstand?

A5: Continuous operation up to 150°C and peak temperatures up to 175°C.

Specifications

| item | Test Method | Unit | Value |

| Density | ASTM D792 | g/cm² | ≤1.8 |

| Tensile Strength | ASTM D2671 | MPa | ≥34.5 |

| Elongation at Break | ASTM D2671 | % | ≥150 |

| Elongation after Aging250°C/168hrs | UL-224 | % | ≥50 |

| Thermal Shock 300°C/4hrs | UL-224 | — | No dripping, No cracking |

| Low-temperature lmpact-55*C/4hrs | UL-224 | — | No cracking |

| Dielectric Strength | ASTM D2671 | KV/mm | ≥31.5 |

| Volume Resistivity | ASTM D257 | Ω·cm | ≥10^13 |

| Flame Resistance Rating | UL-224 | VW-1 | pass |