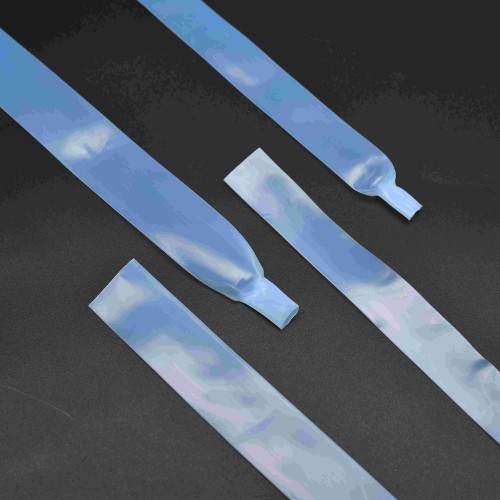

PTFE Heat Shrink is a high-performance tubing made from polytetrafluoroethylene (PTFE), designed to provide exceptional thermal, chemical, and electrical insulation. It shrinks when heated, conforming tightly to wires, cables, or components for protection. Known for its non-stick properties, PTFE heat shrink resists extreme temperatures (-200°C to +260°C), corrosion, and UV exposure. Ideal for aerospace, medical, and industrial applications, it ensures durability in harsh environments. Its low friction coefficient and dielectric strength make it a preferred choice for sensitive electronic assemblies.

Shrink Ratio: (1.7:1)&(2:1)&(4:1)

PTFE (Polytetrafluoroethylene) heat shrink tubing is a high-performance solution for demanding applications. Here are its standout characteristics with supporting technical data:

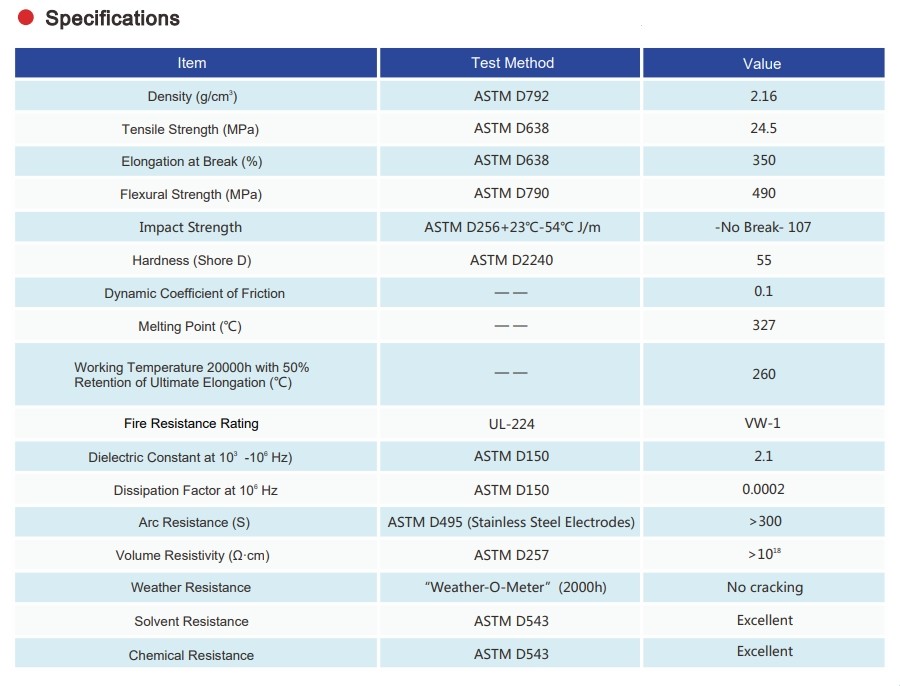

1. Extreme Temperature Resistance: With a continuous service range from -200°C to +260°C (-328°F to +500°F), PTFE heat shrink maintains structural integrity where conventional polymers fail. It withstands intermittent peaks up to 300°C (572°F) without degradation.

2. Chemical Inertness: Demonstrating <1% weight change after 168-hour immersion in concentrated acids (H2SO4 98%), bases (NaOH 50%), and solvents (acetone), PTFE offers superior chemical resistance compared to FEP or PVC alternatives.

3. Low Friction Coefficient: With a dynamic coefficient of friction as low as 0.04-0.10 (ASTM D1894), PTFE heat shrink provides excellent non-stick properties, reducing mechanical wear in dynamic applications.

4. High Dielectric Strength: The material exhibits dielectric breakdown voltage >20 kV/mm (ASTM D149) with volume resistivity >1018 Ω·cm, making it ideal for high-voltage insulation (up to 600V rated).

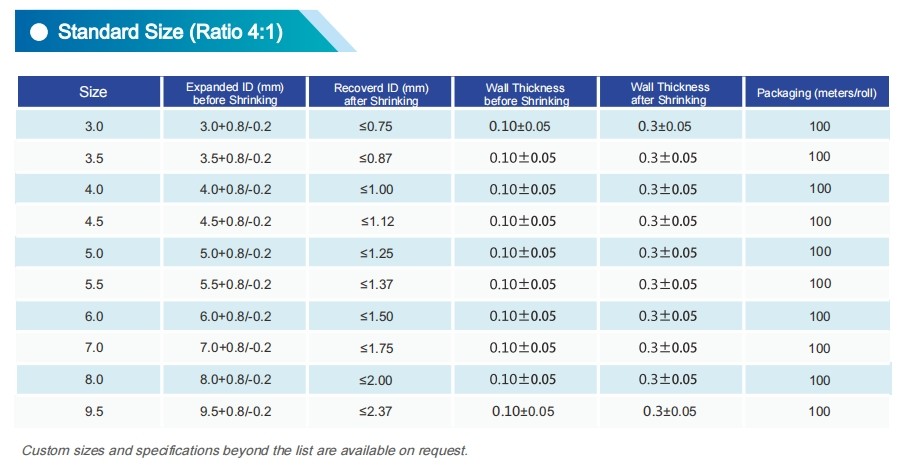

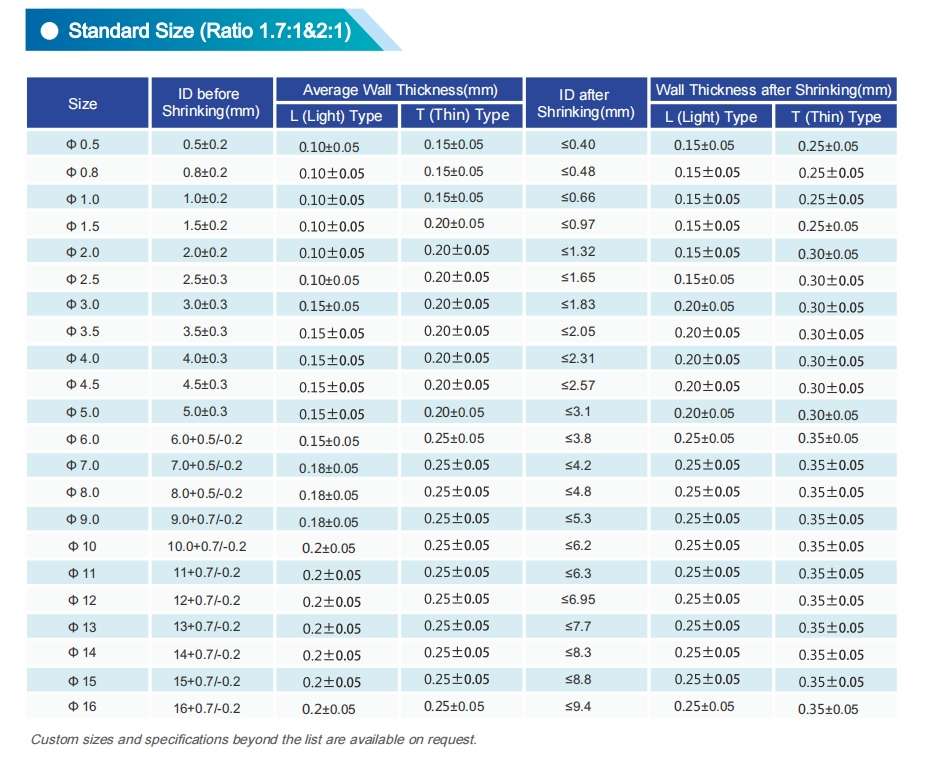

5. Precision Shrink Ratio: Available in 2:1 and 4:1 shrink ratios with ±5% dimensional tolerance (MIL-DTL-23053/4 standards), ensuring consistent recovery rates and wall thickness uniformity post-shrinkage.

6. Ultra-Low Outgassing: Total mass loss (TML) <0.1% and collected volatile condensable materials (CVCM) <0.01% (NASA SP-R-0022A), meeting stringent requirements for aerospace and vacuum applications.

Product Advantages

Product AdvantagesReliable Protection: PTFE heat shrink tubing provides excellent protection against chemical corrosion, high temperatures, humidity, and other environmental factors.

Easy Installation: By heat shrinking, PTFE heat shrink tubing is easy to install and can conform to various shapes of objects.

Durability: Due to PTFE's durability, heat shrink tubing maintains stable performance during long-term use.

Versatility: PTFE heat shrink tubing is used in various applications in the electronics, aerospace, medical, and industrial fields.

GD-PTFE complies with RoHS, REACH, and FDA requirements.

GD-PTFE obtained UL/C-UL flame resistance certifications, meeting the VW-1 flame resistance rating.

Application Fields

Application FieldsAerospace & Defense - Used for wire insulation in aircraft and military equipment due to its extreme temperature resistance (-200°C to +260°C) and chemical inertness.

Medical Devices - Ideal for surgical tools and diagnostic equipment sterilization as PTFE withstands autoclaving and resists bodily fluids.

Chemical Processing - Protects sensors and wiring in corrosive environments where acids or solvents would degrade standard materials.

High-Temperature Electronics - Provides insulation for automotive, industrial, and power generation wiring exposed to heat.

Food & Beverage Equipment - NSF-approved grades meet hygiene standards for processing machinery while resisting grease and cleaning chemicals.

FAQ:

1. What is PTFE Heat Shrink?

PTFE heat shrink is a type of tubing made from polytetrafluoroethylene (PTFE) that shrinks when heated, providing insulation and protection for wires, cables, and components in high-temperature environments.

PTFE heat shrink offers excellent chemical resistance, high-temperature stability (up to 260°C), low friction, and electrical insulation, making it ideal for aerospace, medical, and industrial applications.

Unlike standard PVC or polyolefin heat shrink, PTFE variants withstand extreme temperatures and harsh chemicals while maintaining flexibility and dielectric strength.

Common applications include wire harnesses in aviation, medical device insulation, semiconductor manufacturing, and chemical processing equipment due to its durability and non-reactivity.

Use a heat gun at 300-400°F (150-200°C), evenly applying heat until the tube conforms tightly to the substrate. Avoid open flames to prevent degradation.