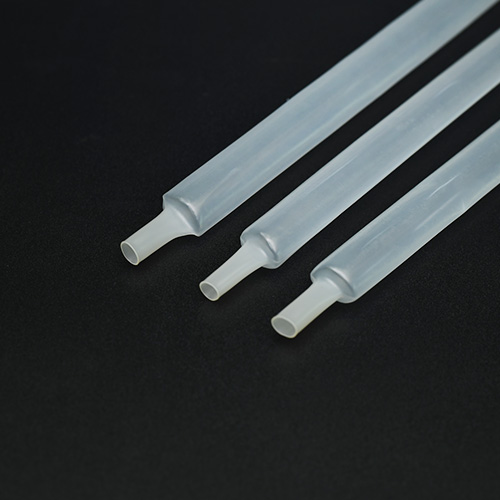

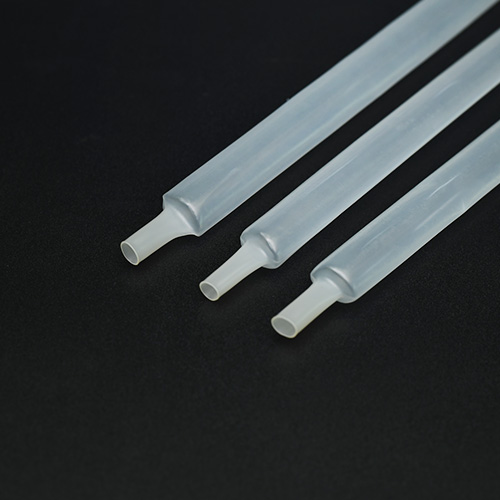

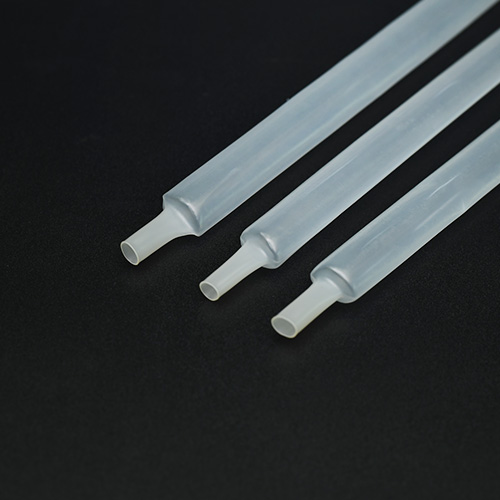

Our Kynar Tubing, made from 100% virgin PVDF, offers exceptional chemical resistance, high purity, and outstanding thermal stability. This Kynar plastic tubing is ideal for transporting corrosive and aggressive fluids in semiconductor, chemical, and industrial systems. Whether used as Kynar PVDF pipe or flexible tubing, it maintains structural integrity even in extreme heat and harsh chemical environments.

Key Features of Kynar PVDF Tubing and Piping:

Key Features of Kynar PVDF Tubing and Piping:

Excellent resistance to acids, bases, and organic solvents, ideal for use as Kynar PVDF piping in chemical environments.

Operating temperatures up to 150°C (302°F)

UV and weather resistant for outdoor and industrial use, making it suitable as red Kynar piping for solar and external systems.

Flame-retardant and FDA-compliant options available

Smooth inner surface for low friction, minimal contamination, and efficient flow

Available in flexible Kynar tubing or rigid Kynar PVDF pipe formats

Product Advantages:

Superior Protection

The material's resistance to chemicals, UV light, and oxidation protects fluid systems and cables from environmental damage. Kynar tubing outperforms many traditional plastic tubing materials in harsh conditions.

Stable Performance

It maintains electrical and mechanical performance even in extreme temperatures and corrosive atmospheres—making it ideal as Kynar PVDF tubing in high-stress systems.

Extended Product Life

Durability, anti-aging properties, and low reactivity help prolong the life of processing systems, whether using flexible Kynar tubing or rigid Kynar piping.

Environmental Adaptability

Suitable for outdoor, high humidity, and chemically aggressive environments, including systems requiring red Kynar piping for safety and fluid line identification.

Ease of Installation

The lightweight and heat-shrinkable nature of Kynar plastic tubing allows for quick, safe, and efficient installation even in confined spaces.

Application Areas

1. Chemical Processing with Kynar Tubing and PVDF Piping

Use Case: Transport of aggressive acids, solvents, and corrosive chemicals

Why Kynar: Exceptional chemical resistance, high purity, and low permeability

Industries: Chemical plants, refineries, electroplating, acid dosing systems

Kynar Benefit: Rigid and flexible Kynar PVDF pipe configurations are both compatible with highly corrosive fluids

2. Semiconductor Manufacturing

Use Case: Ultra-clean fluid transport in wafer fabrication and chip production

Why Kynar: Low extractables, ultra-high purity, compatible with aggressive etchants

Industries: Semiconductor fabs, cleanrooms, electronics production

Kynar Benefit: Preferred Kynar tubing for high-purity chemical lines and DI water

3. Pharmaceutical & Biotechnology

Use Case: Transferring sterile media and harsh cleaning agents

Why Kynar: Biocompatible, sterilizable, compliant with FDA and USP Class VI

Industries: Biotech labs, pharmaceutical production, vaccine facilities

Kynar Benefit: Kynar plastic tubing ensures sterile transport without contamination

4. Water Treatment & Filtration Systems

Use Case: Handling ozone, chlorine, and oxidizers in filtration circuits

Why Kynar: UV resistance, oxidative stability, and long service life

Industries: Industrial water treatment, municipal filtration, ultrapure water systems

Kynar Benefit: Ideal for red Kynar piping installations in safety-coded water treatment systems

5. Food & Beverage Processing

Use Case: Cleaning agent transport and direct fluid contact in food systems

Why Kynar: FDA-compliant, smooth inner walls, resistance to CIP chemicals

Industries: Dairy plants, beverage factories, food dispensing systems

Kynar Benefit: Safe, clean, and long-lasting Kynar PVDF tubing for sanitary fluid lines

FAQ

What is Kynar tubing made of?

Kynar tubing is made from polyvinylidene fluoride (PVDF), a highly durable thermoplastic material known for its chemical resistance and thermal stability.

What are the main applications of Kynar tubing?

Kynar tubing is used in industries such as semiconductor, chemical processing, pharmaceuticals, food and beverage, medical devices, and solar energy systems.

Why is Kynar tubing preferred for high-purity applications?

Kynar tubing is non-contaminating, which makes it ideal for transporting high-purity gases and chemicals in semiconductor and pharmaceutical applications.

Is Kynar tubing resistant to high temperatures?

Yes, Kynar tubing can withstand temperatures up to 150°C (302°F) without compromising its integrity, making it suitable for high-temperature environments.

Can Kynar tubing be used outdoors?

Yes, Kynar tubing has excellent UV and weather resistance, making it suitable for outdoor applications like fluid transport in solar energy systems.