PVDF Heat Shrink Tubing/Kynar Tubing, also known as Kynar tubing, is a high molecular weight thermoplastic polymer known for its excellent resistance to chemicals, high temperatures, UV radiation, and flammability. PVDF is commonly used in environments that demand supreme purity, chemical resistance, and thermal stability.

Chemical Resistance: PVDF exhibits outstanding resistance to a wide range of chemicals, including acids and bases.

Thermal Resistance: The material maintains performance at continuous temperatures up to 150°C and can withstand peaks up to 175°C.

Weatherability: PVDF is highly resistant to UV and radiation, resulting in minimal aging, making it suitable for outdoor applications.

Mechanical Strength: PVDF offers good mechanical strength and toughness, maintaining its physical properties even at low temperatures.

Wear Resistance: It has a high surface hardness and exhibits excellent resistance to wear.

Flame Resistance: PVDF is considered self-extinguishing and not prone to combustion.

Heat Shrinkability: PVDF heat shrink tubing can shrink under the application of heat, conforming to the shape of objects it covers, providing insulation and protection.

Machinability: It can be easily processed by cutting, welding, and forming into various sizes and shapes.

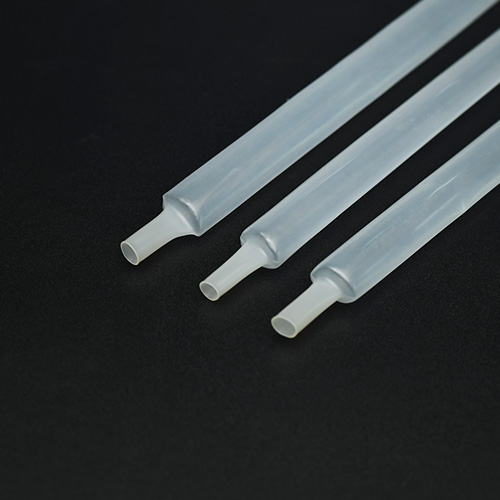

Translucency: Some types of PVDF heat shrink tubing are semi-transparent, allowing for inspection of the underlying object.

High Purity: PVDF materials are free of additives and have minimal contamination potential for fluids and gases, suitable for semiconductor and medical industries.

Product Advantages:

Kynar Plastic Tubing, made from premium PVDF (polyvinylidene fluoride), offers exceptional performance for demanding fluid transfer applications. Renowned for its outstanding chemical resistance, this tubing can safely handle acids, bases, oxidizers, and other highly corrosive liquids, making it ideal for a wide range of industrial and laboratory uses.

Designed to withstand high temperatures, Kynar tubing maintains its integrity under long-term heat exposure up to 150°C, with the capability to endure even higher short-term temperatures. Its robust structure ensures strong pressure resistance, providing safe and reliable fluid conveyance in critical systems. Additionally, the tubing features low permeability, preventing gas or liquid leakage and maintaining the purity of transported fluids.

Kynar Plastic Tubing also excels in mechanical performance, offering superior toughness and flexibility. It is resistant to cracking or breaking and can be easily installed or bent to fit complex piping layouts. The tubing’s excellent weather and UV resistance ensures long-lasting durability, even in outdoor or light-exposed applications.

Application Fields

Chemical Industry: Transporting corrosive liquids, acidic or alkaline solutions, and strong oxidizers.

Semiconductor & Electronics: Fluid delivery systems for high-purity chemicals and cleanroom processes.

Pharmaceuticals & Laboratories: For drug preparation, chemical analysis instruments, and lab fluid transfer.

Water Treatment Systems: Corrosion-resistant pipelines for reverse osmosis and purified water equipment.

Food & Beverage Industry: Safe use in high-temperature, corrosion-resistant fluid transport.

Energy & Environmental Protection: Handling chemical waste, corrosion-resistant fluid pipelines, and related applications.