![]()

silicone rubber tubing is manufactured from high-quality food-grade and medical-grade silicone elastomer. It is designed to withstand extreme temperatures, ranging from -60°C to over +200°C, while maintaining excellent flexibility, durability, and chemical stability. With outstanding thermal properties, electrical insulation, and resistance to aging, UV light, ozone, and radiation, silicone rubber tubing is widely used in medical devices, food processing, electronics, automotive, aerospace, and industrial applications.

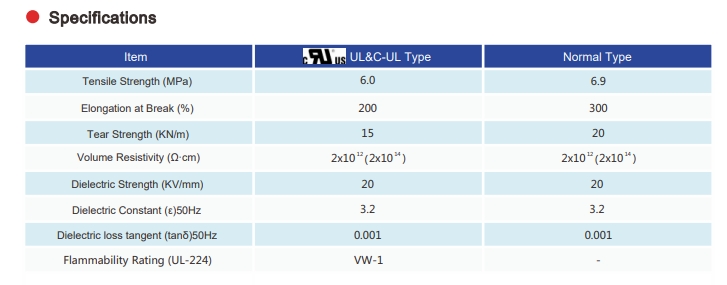

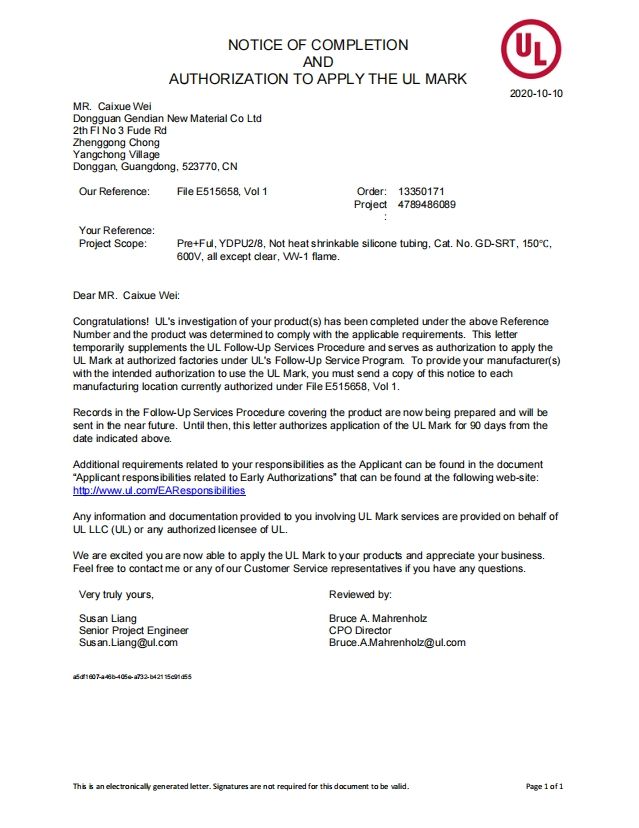

The tubing complies with RoHS, REACH, FDA, and has passed SGS testing. Additionally, it meets UL/C-UL VW-1 flame retardant standards, ensuring safety and reliability in critical environments.

Wide Temperature Resistance: Operates from -60°C to +200°C, suitable for extreme hot and cold environments.

Food-Grade & Biocompatible: Safe for contact with food, beverages, and medical devices.

Durability: Resistant to UV, ozone, radiation, and chemical corrosion.

Excellent Elasticity: Maintains flexibility under bending, compression, and stretching.

Electrical Insulation: High breakdown voltage (25KV/mm) ensures safe use in electronic and electrical systems.

Certifications: SGS tested, RoHS, REACH, FDA compliant, UL flame retardant certified.

![]() High-Temperature Resistance: Silicone tubing can typically operate within a wide temperature range, from extremely low temperatures to high temperatures (from -60°C to well over +200°C). This makes it suitable for various high-temperature applications, such as automotive engine cooling systems and heat exchangers.

High-Temperature Resistance: Silicone tubing can typically operate within a wide temperature range, from extremely low temperatures to high temperatures (from -60°C to well over +200°C). This makes it suitable for various high-temperature applications, such as automotive engine cooling systems and heat exchangers.

Electrical Insulation: Silicone tubing offers excellent electrical insulation properties, making it suitable for use in electronic and electrical engineering to reduce electrical risks.

Flexibility: Silicone tubing is highly flexible, allowing easy bending and installation, making it suitable for various complex wiring and connection requirements, including medical devices and laboratory equipment.

Hygiene: The smooth surface of silicone tubing is easy to clean, making it widely used in medical and food processing applications to ensure hygiene.

Versatility: Silicone tubing provides a wide range of options in terms of sizes, wall thickness, colors, and hardness to meet the specific needs of various applications. This versatility ensures its suitability for industrial and medical applications.

Medical Device Components: Silicone tubing is commonly employed in medical devices such as catheters, drainage tubes, and IV tubing. Its advantages include being non-toxic, bio-compatible, highly breathable, heat-resistant, and resistant to aging, providing stable performance and safety in medical equipment.

Industrial Sectors: Silicone tubing finds use in the transportation and storage of liquids and gases across various industrial sectors, including chemical, petroleum, pharmaceutical, and textile industries. Its benefits encompass corrosion resistance, high-temperature tolerance, high-pressure resistance, and excellent insulating properties, ensuring efficient operation and safety of industrial equipment.

Everyday Consumer Goods: Silicone tubing is used in various daily consumer goods like straws, toothbrushes, gloves, and more. Its advantages lie in being soft, comfortable, corrosion-resistant, and non-toxic, offering convenience and safety in daily life.

In addition to the mentioned applications, silicone tubing is also utilized in other fields. For instance, in the construction industry, silicone tubing is employed in areas such as water pipes, drainage systems, and fire-fighting pipelines. In the aerospace sector, silicone tubing is utilized in fields like fuel transport and air pressure sensing. Furthermore, silicone tubing is applied in electronic devices for sealing and insulation purposes.

The product has undergone SGS testing and complies with environmental requirements, including RoHS, REACH, and FDA standards.

It has also received UL/C-UL flame retardant level certification, meeting the VW-1 flame resistance rating.

Avoid prolonged contact with sharp objects to prevent cutting or tearing.

Do not expose tubing to strong oils or solvents unless using oil-resistant silicone variants.

Ensure correct sizing (inner diameter, wall thickness) to prevent leakage or bursting.

Regularly inspect tubing in medical or industrial applications to ensure safety compliance.

Product Q&A

Compared to alternative tubing materials, silicone rubber tubing stands out with its excellent temperature resistance, flexibility, and resistance to UV radiation and ozone. Understanding these comparisons aids in selecting the most suitable tubing for specific applications.

Yes, silicone rubber tubing is known for its ability to withstand extreme temperatures. This makes it ideal for applications where exposure to high or low temperatures is a critical factor, such as in automotive, aerospace, and industrial settings.

Silicone rubber tubing exhibits resistance to chemicals and environmental factors, making it suitable for applications where exposure to various substances and harsh conditions is common.

When working with silicone rubber tubing, it's important to follow safety precautions, including proper storage, understanding temperature limits, and using appropriate fittings. Adhering to safety guidelines ensures a secure working environment.

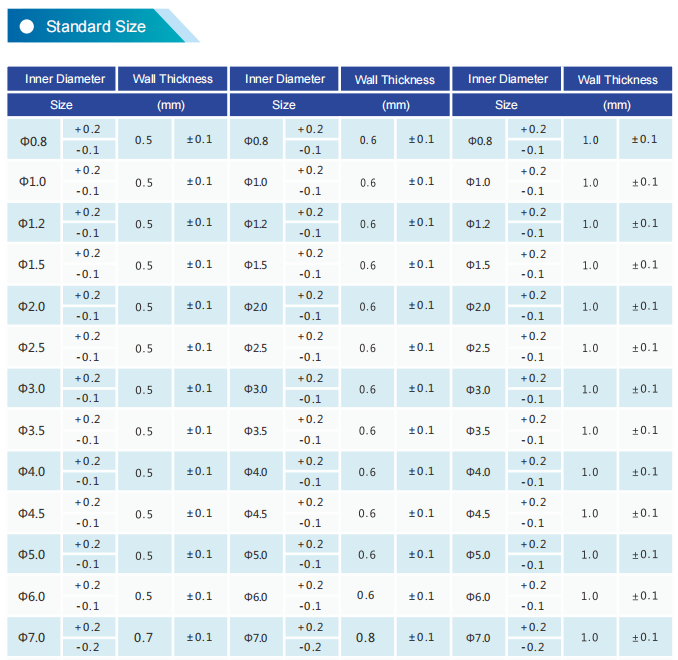

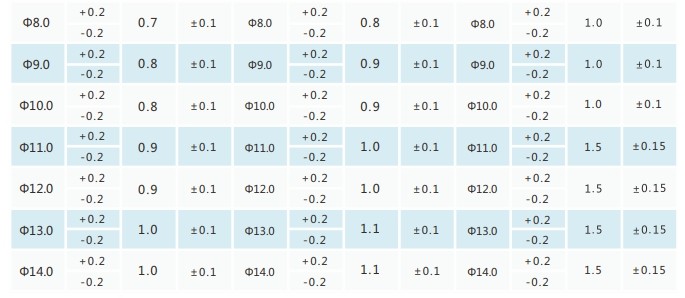

Custom sizes and specifications beyond the list are available on request.

Custom sizes and specifications beyond the list are available on request.