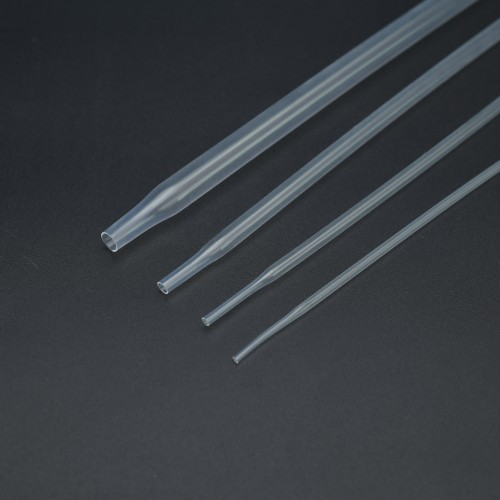

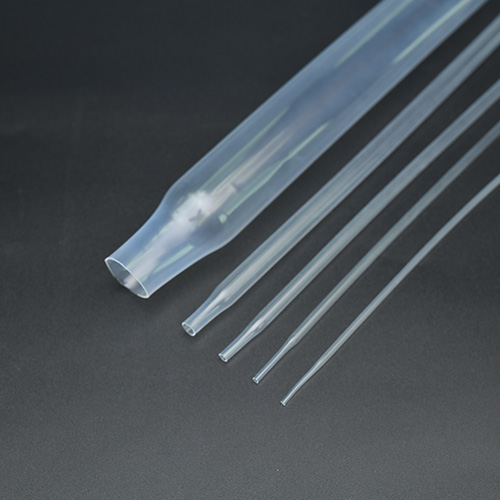

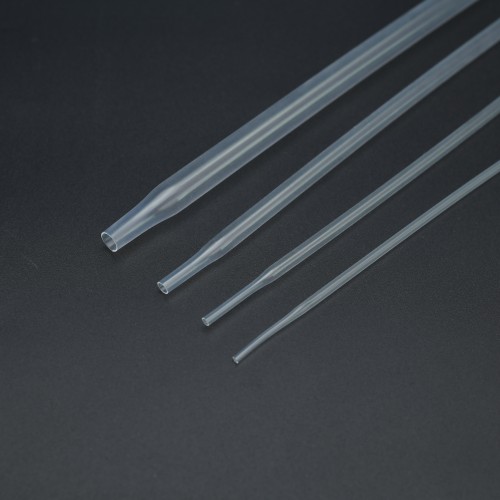

FEP HEAT SHRINK TUBING(Shrink Ratio: (1.3:1)&(1.6:1)&(2:1))

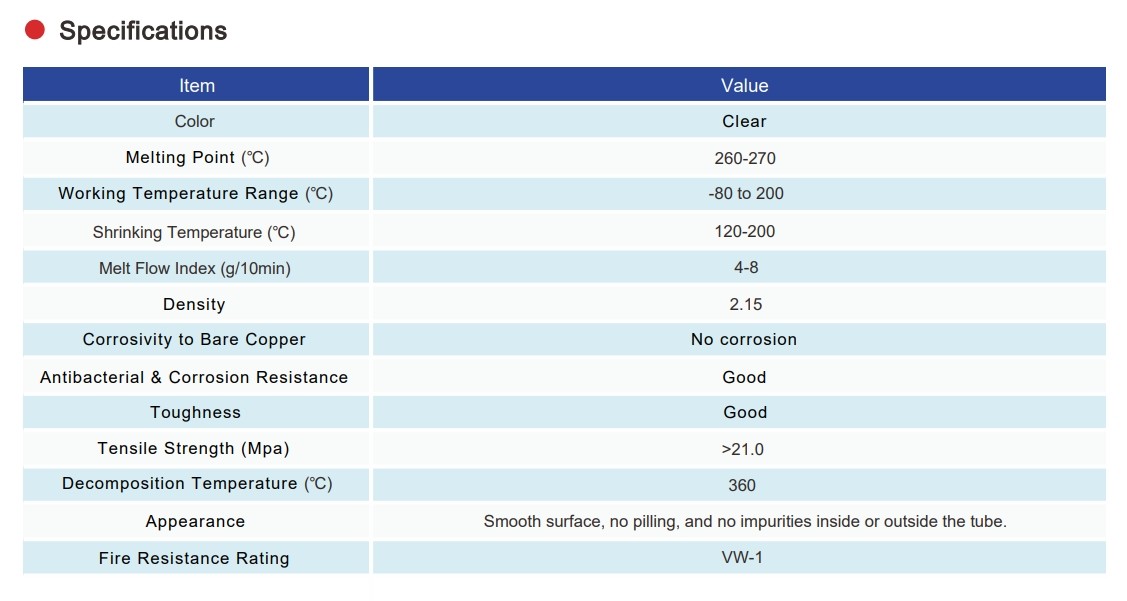

Our FEP, PFA, and ETFE Heat Shrink Tubing is a family of high-performance fluoropolymer heat shrink products designed for demanding applications that require superior thermal resistance, chemical stability, electrical insulation, and mechanical protection. These materials are lightweight, transparent, and capable of withstanding a wide temperature range, making them ideal for use in harsh industrial, medical, and aerospace environments.

FEP (Fluorinated Ethylene Propylene): Offers excellent low-temperature flexibility and optical clarity, making it perfect for visual inspection applications.

PFA (Perfluoroalkoxy): Provides exceptional chemical resistance and long-term high-temperature performance, ideal for semiconductor and pharmaceutical processing.

ETFE (Ethylene Tetrafluoroethylene): Known for superior mechanical strength, abrasion resistance, and radiation tolerance, making it suitable for heavy-duty and high-stress environments.

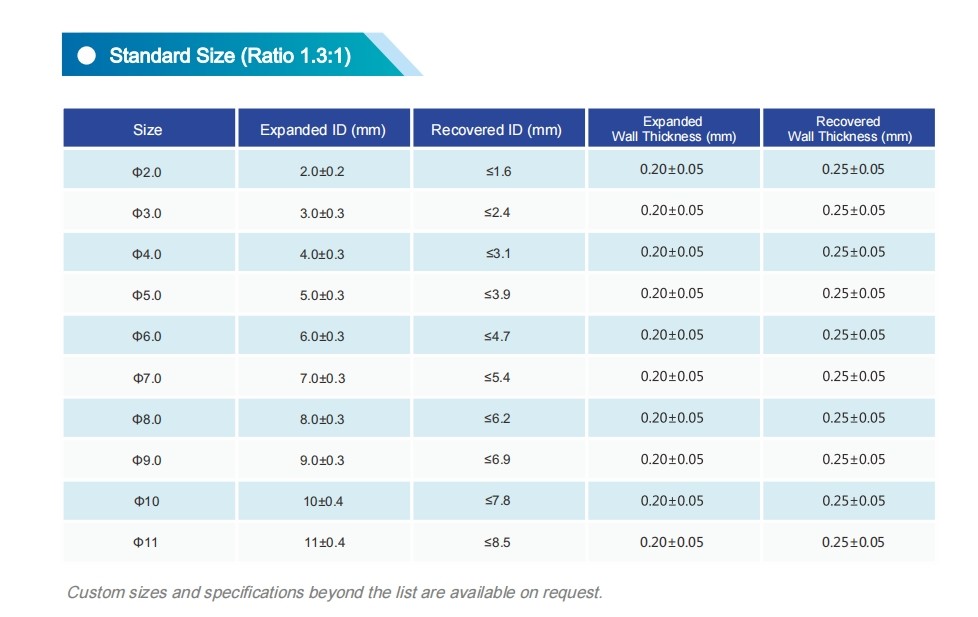

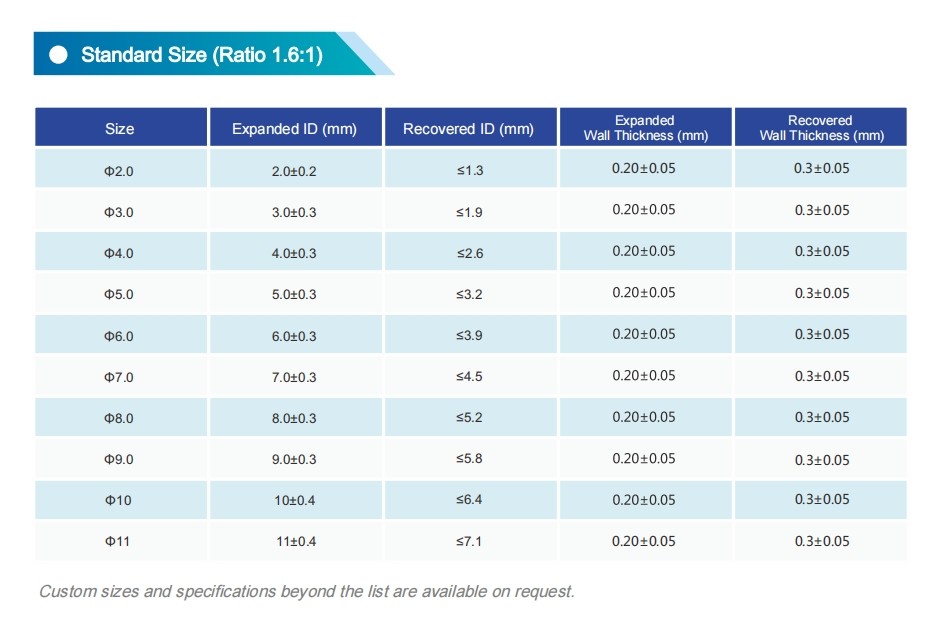

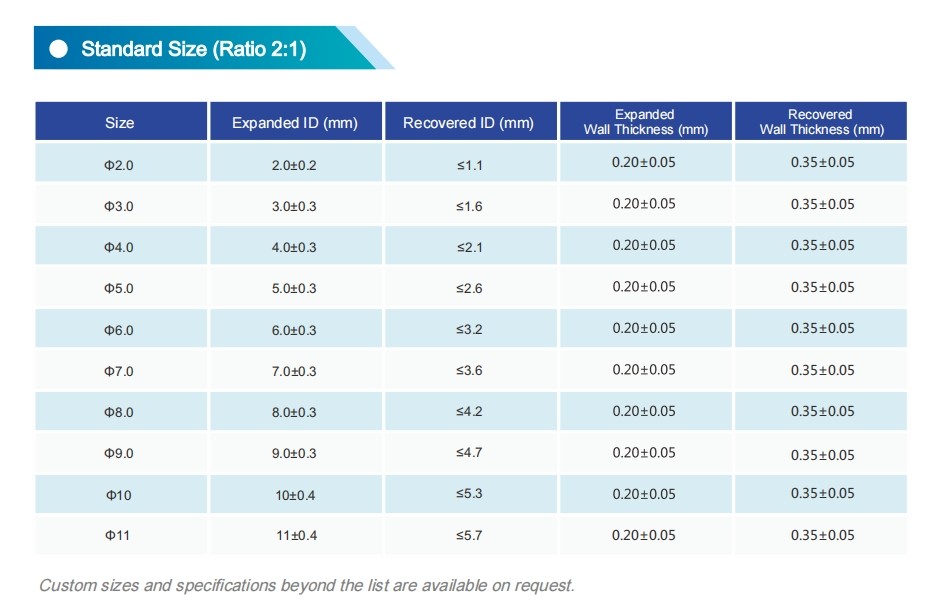

Available in multiple shrink ratios (1.3:1, 1.6:1, 2:1), these heat shrink tubes tightly conform to a variety of shapes and diameters, ensuring reliable sealing and protection for cables, wires, connectors, and equipment.

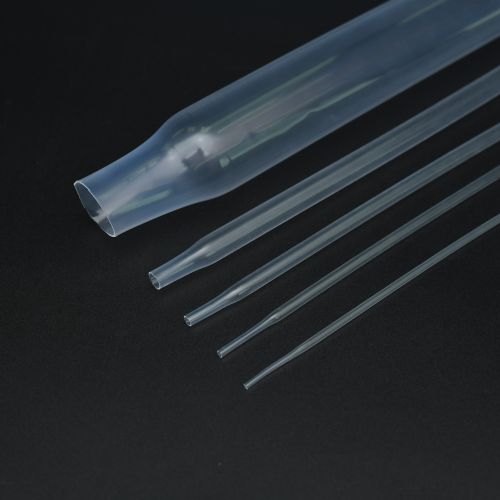

Wide Operating Temperature Range

Functional from -200°C to +200°C (short-term up to 260°C), making it suitable for both cryogenic and high-heat applications.

PFA offers the highest thermal endurance, ideal for processes requiring continuous high-temperature exposure.

Excellent Chemical Resistance

Nearly unaffected by strong acids, alkalis, solvents, and most corrosive chemicals.

PFA is particularly suited for high-purity chemical environments due to its extremely low leach-out rates.

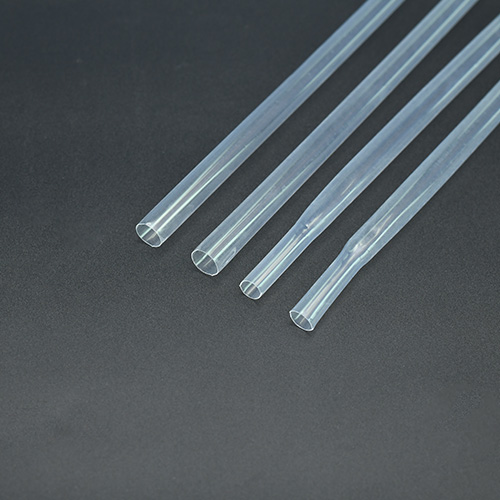

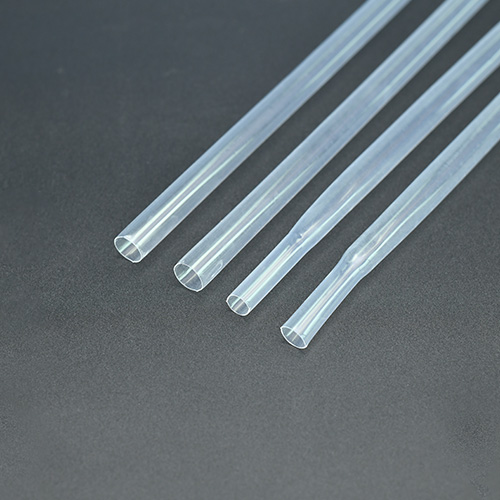

High Transparency

FEP and PFA offer excellent optical clarity for visual inspection of internal cables, fluids, or connectors.

Useful for monitoring critical systems without disassembly.

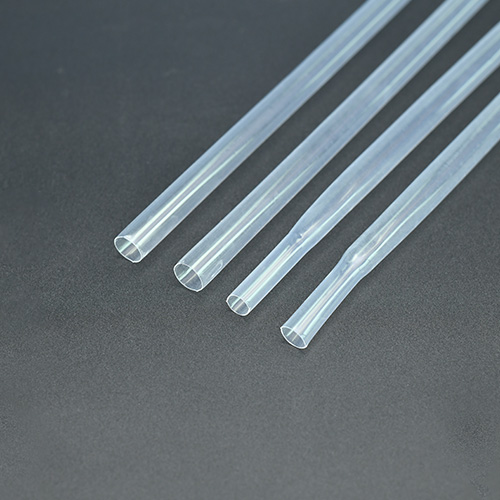

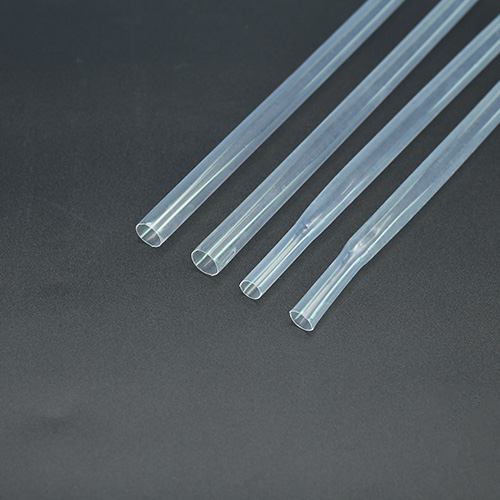

Dimensional & Mechanical Stability

Retains shape and dimensions under thermal cycling and mechanical stress.

ETFE provides superior tensile strength and impact resistance, protecting components in high-vibration or abrasion-prone environments.

Low Friction & Non-Stick Surface

Smooth surface resists adhesion and buildup of contaminants, making cleaning and maintenance easier.

Ideal for roller coatings, wiring harnesses, and dynamic equipment.

Regulatory Compliance

Meets RoHS, REACH, and FDA standards, suitable for use in food contact and medical device applications.

GD-FEP has passed UL/C-UL VW-1 flame resistance certification, ensuring fire safety compliance.

Reliable Protection: Chemical inertness and low permeability ensure long-term defense against corrosion, moisture, and environmental stress.

Ease of Installation: Controlled shrink ratios guarantee predictable, uniform shrinkage and a tight, professional fit.

Long-Term Durability: Exceptional thermal stability, UV resistance, and crack resistance minimize aging and reduce maintenance costs.

Application Versatility: Covers a wide range of industries — electronics, aerospace, chemical processing, food manufacturing, and medical equipment.

Global Compliance: Pre-certified for RoHS, REACH, FDA, and flame resistance, simplifying international approvals and product certification processes.

Electronics & Electrical: Cable insulation, connector encapsulation, high-voltage wiring protection.

Medical Equipment: Non-toxic, transparent protection for endoscopes, sensors, and catheters.

Chemical & Laboratory: Corrosion-resistant coating for tubing, sensors, and fluid transport lines.

Food Processing: Direct food-contact applications, contamination prevention for piping systems.

Aerospace & Automotive: Abrasion-resistant protection for wire harnesses and exterior sensors.

Construction & Industrial: Roller wrapping, protective coatings, and harsh outdoor applications.

Pre-measure tubing length before installation to ensure proper coverage.

Use a controlled heat source (e.g., hot air gun or oven) to ensure even shrinkage and avoid overheating.

Avoid exposure to open flame to prevent surface degradation.

Store in a cool, dry place away from direct sunlight to maintain material properties.

Q1: What shrink ratios are available?

A: We offer 1.3:1, 1.6:1, and 2:1 shrink ratios, suitable for a range of component sizes and shapes.

Q2: Can this tubing be used in high-temperature applications?

A: Yes. FEP can operate up to 200°C (260°C short term), while PFA supports continuous use up to 260°C, making it suitable for semiconductor, pharmaceutical, and thermal cycling processes.

Q3: Is the tubing food-safe?

A: Yes, both FEP and PFA comply with FDA requirements, making them suitable for food contact and cleanroom applications.

Q4: How does ETFE differ from FEP/PFA?

A: ETFE offers higher mechanical strength, abrasion resistance, and radiation tolerance, making it ideal for high-stress or high-radiation environments such as aerospace and nuclear applications.

Q5: How should the tubing be heated for shrinking?

A: Use a hot air gun or oven at controlled temperatures to achieve uniform shrinkage. Avoid direct flame contact to prevent surface damage.

Our GD-FEP, PFA, and ETFE complies with RoHS, REACH, and FDA requirements.

Our GD-FEP has passed UL/C-UL Flame resistance test, meeting the VW-1 flame resistance rating.