FEP SPRIAL WRAP/CUT TUBING, made of high quality FEP material, has excellent electrical insulation and high temperature resistance. Its spiral design facilitates the flexible wrapping of various shapes of wires and cables, and it is easy to cut and adjust the length according to the demand. The product can effectively prevent wire and cable from mechanical damage and chemical corrosion, and safeguard the safe and stable operation of equipment. At the same time, it also has excellent abrasion resistance and aging resistance, and is not easy to be deformed or aged for a long time.

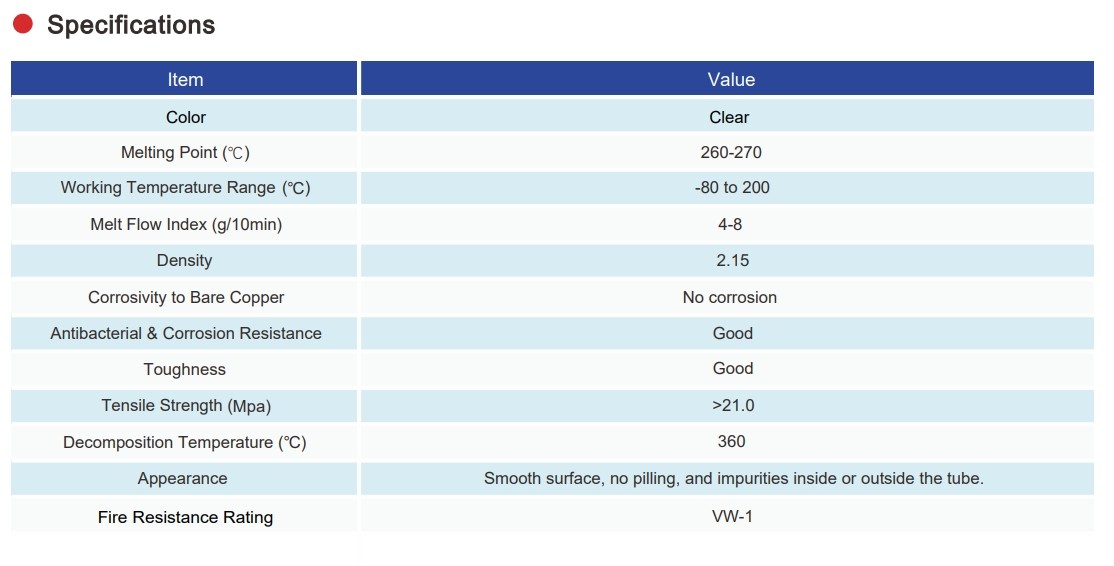

Thermal Resistance: FEP has a melting point of approximately 260°C (500°F) and maintains its mechanical properties and dimensional stability across a wide temperature range.

Chemical Resistance: FEP exhibits remarkable resistance to virtually all industrial chemicals, from strong acids and bases to oxidizers, hardly affected by them.Electrical

Properties: Exhibits a very low dielectric constant and power factor, making FEP an excellent insulating material for cables.

High Transparency: The transparency of FEP material allows for visual inspection of the condition of wires and cables.

UV and Weather Resistance: FEP has excellent resistance to UV rays and weather conditions, making it suitable for outdoor applications.

Non-stick Surface: The non-stick nature of the FEP surface means dust and other contaminants are less likely to adhere, making it easy to clean.

Product Features

FEP Spiral Wrap for Wire Protection

This wrap is engineered to provide exceptional wire protection in high-performance environments. The FEP material shields wires and cables from abrasion, mechanical stress, and wear during movement or vibration.

Transparent FEP Spiral Tubing for Cable Bundling

Designed with a transparent fluoropolymer construction, this spiral tubing allows for easy cable identification and monitoring without removing the wrap. Perfect for neat, professional cable bundling in control panels and enclosures.

Heat Resistant Spiral Wrap Cable Organizer

With outstanding thermal stability, the FEP spiral wrap can operate continuously in temperatures up to 200°C. This makes it an ideal cable organizer for use near heat-generating equipment and components.

Chemical Resistant Spiral Wrap for Laboratory Equipment

Made from fluorinated ethylene propylene, this wrap provides superior chemical resistance against acids, bases, solvents, and corrosive gases—making it highly suitable for laboratory, pharmaceutical, and cleanroom wiring applications.

Flexible FEP Spiral Wrap for Industrial Wiring

The spiral design allows for easy installation, removal, and flexibility around tight bends and confined spaces. This flexible FEP spiral wrap is perfect for industrial wiring harnesses, machinery, and automation systems.

Low Maintenance Cost: Due to its durability, FEP spiral wrap tubing reduces the need for frequent maintenance and replacement.

Enhanced Safety: The protection provided helps prevent cable failure, reducing the risks of fire and malfunctions.

Complex Environment Adaptation: FEP spiral wrap tubing delivers stable performance in extreme temperatures, corrosive chemicals, or high electrical insulation requirements.Space-saving: Compared to other protective tubing materials, FEP spiral wrap can be more compactly fitted around cables, aiding in effective space utilization.

Electronics and Semiconductor Equipment

Ideal for bundling sensitive signal wires and power cables in high-precision electronics manufacturing systems, where chemical resistance and cleanliness are critical.

Laboratory and Medical Environments

Widely used in laboratories, cleanrooms, and medical equipment where exposure to harsh chemicals, sterilization processes, and temperature variation requires transparent and chemically resistant wire protection.

Aerospace and Aviation Systems

Suitable for aircraft wire harnessing, where weight, heat resistance, and vibration protection are crucial. FEP spiral wrap performs reliably in extreme temperature and pressure conditions.

Industrial Automation and Robotics

Applied in industrial wiring and flexible cable routing on robotics arms, CNC machines, and automated conveyors where durability, flexibility, and easy maintenance are important.

Telecommunication and Network Cabinets

Helps maintain cable order and visibility in data centers and telecom installations, especially where transparent FEP spiral tubing allows quick identification of bundled wires.

Chemical Processing Plants

Ideal for use in chemical factories and fluid handling systems, where acid, solvent, and oil resistance are required for long-term cable protection and insulation.

Compared to other types of tubing, FEP SPIRAL WRAP/CUT TUBING offers improved strength and flexibility, as well as exceptional corrosion resistance and high temperature capabilities. It also has a longer lifespan than many other types of tubing.

The performance of FEP SPIRAL WRAP/CUT TUBING is affected by its unique properties, including its high strength-to-weight ratio, exceptional flexibility, and corrosion resistance. These properties allow the tubing to handle high pressure, resist wear and tear, and maintain its structural integrity over time.

When using FEP SPIRAL WRAP/CUT TUBING, it's important to consider safety considerations such as using appropriate installation methods and following manufacturer's instructions. It's also important to ensure the tubing is properly supported and secured to prevent stress or damage.

FEP SPIRAL WRAP/CUT TUBING is typically manufactured using a combination of extrusion and wrapping processes. The FEP material is extruded into thin-walled tubes and then wrapped to form the spiral structure. The process involves precision control to ensure the tubing has the desired dimensions and properties.

The cost ofFEP SPIRAL WRAP/CUT TUBING varies depending on the size, length, material, and other factors. It's generally more expensive than standard straight tubing but offers improved performance and longer lifespan.

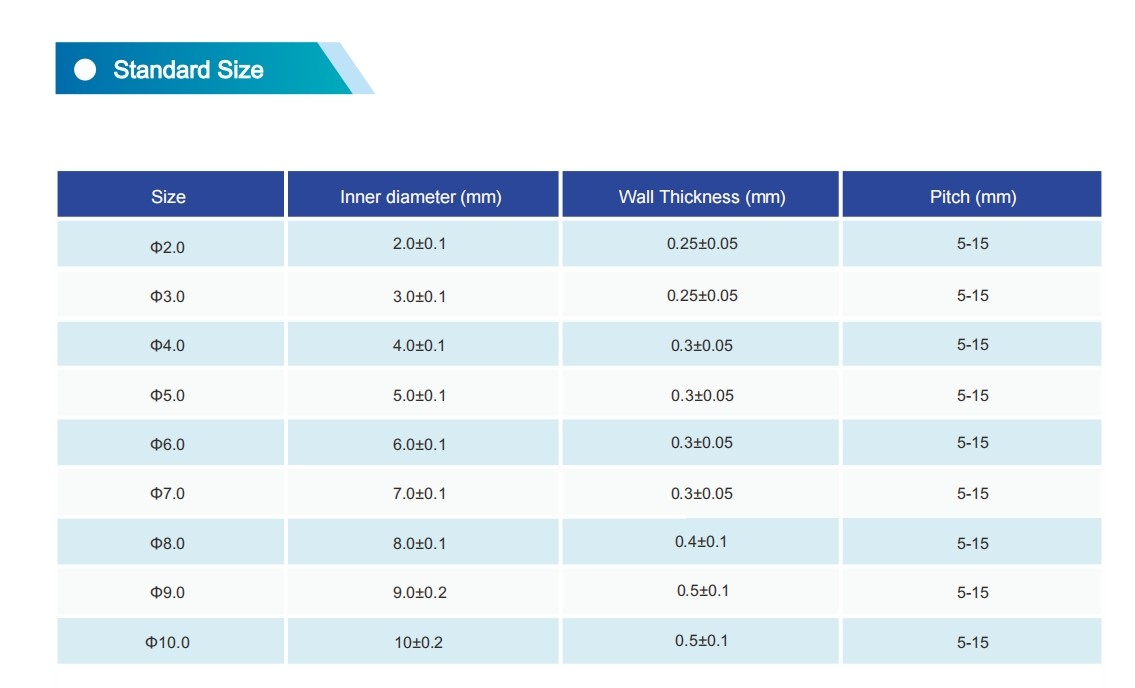

The dimensions of FEP SPIRAL WRAP/CUT TUBING vary depending on the size and type but are generally available in standard diameters ranging from small tubes to large industrial-sized pipes. The tubing is typically available in standard lengths and can be cut to size as needed.

Compared to other types of tubing materials, FEP SPIRAL WRAP/CUT TUBING offers superior performance in terms of its high strength-to-weight ratio, exceptional flexibility, corrosion resistance, and high temperature capabilities. It also has a longer lifespan than many other types of tubing, resulting in lower replacement costs and increased value

Our FEP SPIRAL WRAP/CUT TUBING complies with RoHS, REACH, and FDA requirements.

It also meets the VW-1 flame resistance rating.

Custom sizes and specifications beyond the list are available on request.

Custom sizes and specifications beyond the list are available on request.